Cast Iron (EN-GJS)

Materials Cast iron

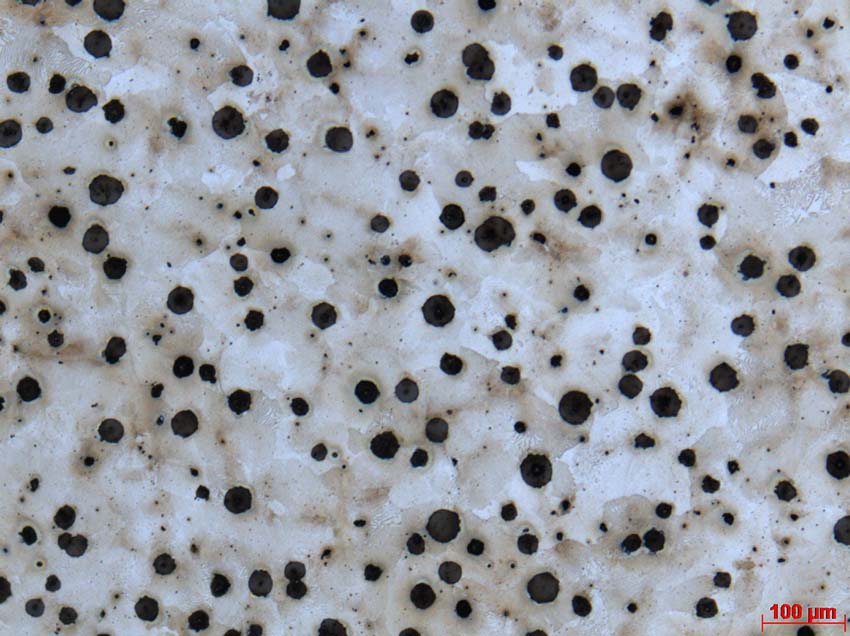

Ductile iron is not a single material but is part of a group of materials which can be produced to have a wide range of properties through control of the microstructure. The common defining characteristic of this group of materials is the shape of the graphite. In ductile irons, the graphite is in the form of nodules rather than flakes as it is in grey iron. The sharp shape of the flakes of graphite create stress concentration points within the metal matrix and the rounded shape of the nodules less so, thus inhibiting the creation of cracks and providing the enhanced ductility that gives the alloy its name.The formation of nodules is achieved by the addition of nodulizing elements, most commonly magnesium (note magnesium boils at 1100°C and iron melts at 1500°C) and, less often now, cerium (usually in the form of Mischmetal). Tellurium has also been used. Yttrium, often a component of Misch metal, has also been studied as a possible nodulizer.

Technological and physical values

| Item according to DIN EN 1563 |

Measure | Unit | EN-GJS-350-22-LT EN-JS 1015 |

EN-GJS-400-18-LT EN-JS 1025 |

EN-GJS-400-18 EN-JS 1020 |

EN-GJS-500-7 EN-JS 1050 |

EN-GJS-600-3 EN-JS 1060 |

EN-GJS-700-2 EN-JS 1070 |

EN-GJS-800-2 EN-JS 1080 |

|---|---|---|---|---|---|---|---|---|---|

| Tensile Strength 1) | Rm | min.MPA | 350 | 400 | 400 | 500 | 600 | 700 | 800 |

| 0.2% Yield Strength 1) | Rp0,2 | min.MPA | 220 | 240 | 250 | 320 | 370 | 420 2) | 480 2) |

| Elongation Strength 1) | A | % | 22,0 | 18,0 | 18,0 | 7,0 | 3,0 | 2,0 | 2,0 |

| Brinell hardness | HB | 110-150 | 120-160 | 140-190 | 170-220 | 200-250 | 230-280 | 250-330 | |

| Structures | ferritisch | ferritisch | ferritisch | ferlitisch perlitisch | perlitisch ferlitisch | perlitisch | perlitisch | ||

| ISO-V impact test by -40 ± 2 ºC |

12,0 | ||||||||

| ISO-V impact test by -20 ± 2 ºC |

12,0 | ||||||||

| ISO-V impact test by +23 ± 5 ºC |

Kv | min.J | 17,0 3) | 14,0 3) | |||||

| Shear Stress | σaB | MPa | 315 | 360 | 360 | 450 | 540 | 630 | 720 |

| Torsion | TtB | MPa | 315 | 360 | 360 | 450 | 540 | 630 | 720 |

| Modules of elasticity (pull and push) |

E | GPa | 170 | 170 | 170 | 175 | 175 | 175 | 175 |

| Poisson number | v | – | 0,280 | 0,280 | 0,280 | 0,280 | 0,280 | 0,280 | 0,280 |

| Constant Swing Strength (in bending test) 4) uncarved trial (Ø10,6mm) |

σD | MPa | 180 | 195 | 195 | 224 | 248 | 280 | 304 |

| Constant Swing Strength (in bending test) 4) notched test (Ø10,6mm) |

σD | MPa | 114 | 122 | 122 | 134 | 149 | 168 | 182 |

| Constant resistance to tensile and compressive claim |

δzdW | MPa | ±100 | ±110 | ±110 | ±150 | ±175 | ±200 | – |

| Compressive Strength | σdB | MPa | – | 700 | 700 | 800 | 870 | 1000 | 1150 |

| Frature Toughness | Klc | MPa ·√m | 31 | 30 | 30 | 25 | 20 | 15 | 14 |

| Density | g/cm3 | 7,1 | 7,1 | 7,1 | 7,1 | 7,2 | 7,2 | 7,2 |

Test piece after DIN EN 1563

1) properties in a separately cast test piece

2) higher values when distributed

3) target values

4) test for constant strength

5) 10,6mm Ø at the 45º point notch with 0,25mm radius

Casting involved mechanical properties

| Wall thickness (mm) | Expectaition Values in the casting, min. | ||||

|---|---|---|---|---|---|

| from | to | Tensile Strength [MPa] | 0.2% Yield Strength [MPa] | Elongation Strength [%] | |

| EN-GJS-350-22U-LT EN-JS 1019 |

30 60 |

30 60 200 |

350 330 320 |

220 210 200 |

22 18 15 |

| EN-GJS-400-18U-LT EN-JS 1049 |

30 60 |

30 60 200 |

400 390 370 |

240 230 220 |

18 15 12 |

| EN-GJS-400-18U EN-JS 1062 |

30 60 |

30 60 200 |

400 390 370 |

250 250 240 |

18 15 12 |

| EN-GJS-500-7U EN-JS 1082 |

30 60 |

30 60 200 |

500 450 420 |

320 300 290 |

7 7 5 |

| EN-GJS-600-3U EN-JS 1092 |

30 60 |

30 60 200 |

600 600 550 |

370 360 340 |

3 2 1 |

| EN-GJS-700 2U EN-JS 1102 |

30 60 |

30 60 200 |

700 700 660 |

420 400 380 |

2 2 1 |

Discuss warranty of properties in special case. Targeted standards also make it possible to achieve higher values in processing. Material meaning according to DIN/EN 1563 (cast test piece).

Mechanical properties of molded specimen

| Wall thickniss in the casting [mm] |

Thickniss molded specimen [mm] |

EN-GJS-350-22U-LT EN-JS 1019 |

EN-GJS-400-18U-LT EN-JS 1049 |

EN-GJS-400-18U EN-JS 1062 |

EN-GJS-500-7U EN-JS 1082 |

EN-GJS-600-3U EN-JS 1092 |

EN-GJS-700-2U EN-JS 1102 |

|

|---|---|---|---|---|---|---|---|---|

| Tensile Strength Rm min. [MPa] |

30-60 60-200 |

40 70 |

330 320 |

390 370 |

390 370 |

450 420 |

600 550 |

700 660 |

| 0.2% Yield Strength Rp0,2 min. [MPa] |

30-60 60-200 |

40 70 |

210 200 |

230 220 |

250 240 |

300 290 |

360 340 |

400 380 |

| Elongation Strength A min. [%] | 30-60 60-200 |

40 70 |

18,0 15,0 |

15,0 12,0 |

15,0 12,0 |

7,0 5,0 |

2,0 1,0 |

2,0 1,0 |

| Notched test Kv min. [J] by -20 ± 2 ºC (with 3 tests) |

30-60 60-200 |

40 70 |

12,0 1) 10,0 1) |

12,0 10,0 |

– | – | – | – |

| Notched test Kv min. [J] by +23 ± 5 ºC (with 3 tests) |

30-60 60-200 |

40 70 |

17,0 2) 15,0 2) |

14,0 2) 12,0 2) |

– | – | – | – |

1) This value at -40 ± 2 ºC; 2) Guideline values This table mainly applies to castings above 2000 kg and/or wall thickness from 50 to 200 mm.